The term bioplastic is currently one of those that generates a bit of confusion, and rightly so, since different concepts are encompassed by the same term. Let’s explore them together!

According to European Bioplastics, the European association representing the industry, bioplastics are those:

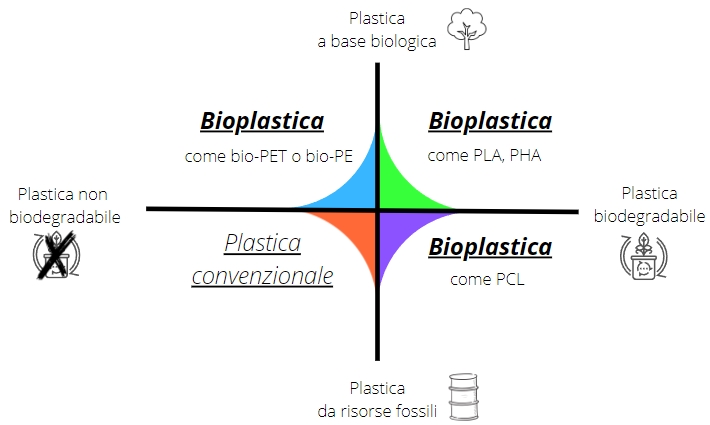

- biodegradable (or bio-degradable in English), meaning that over time, they undergo a chemical process in which microorganisms in the environment convert the materials into natural substances such as water, carbon dioxide, and compost without the need for chemical additives

- bio-based (or bio-based in English), meaning they are composed of materials derived from biomass, such as corn, sugar cane, or cellulose

Attention! Biodegradable plastics are not necessarily bio-based, and bio-based plastics are not necessarily biodegradable! To clarify, we have created the following chart.

Another point of view

Assobioplastiche, the Italian association of the biodegradable and compostable materials sector, has a different school of thought and suggests not using the term bioplastics to refer to bio-based plastics, which will instead be called plant-based plastics. According to Assobioplastiche’s definition, bioplastics are only those that are biodegradable and compostable, whether of biological or fossil origin.

To further complicate matters, as already seen in other articles from the Plastic Observatory, the biodegradability and compostability of plastic should not be confused because they refer to two related but not exactly the same properties.

In short, for a material to be defined as biodegradable and compostable, it must meet different requirements than those for biodegradability alone. To be compostable according to the technical standard UNI EN 13432:2002, the material must degrade by 90% in 6 months, disintegrate by at least 90% into fragments smaller than 2 mm within 3 months, and the absence of negative effects on the composting process and the final compost must be verified. Even the symbols used to indicate that the product has been evaluated as conforming to compostability tests are different from the generic ones used for biodegradability.

What is bioplastic used for?

Regardless of the definition, bioplastics have great potential to mitigate the end-of-life disposal problem and/or the use of finite resources for their production, such as petroleum.

According to Bioplastics Europe, in 2019, about 1% of the world’s plastic production was bioplastic, with 55% being biodegradable plastic and the remaining 45% being biomass-based but non-biodegradable plastic. Predictions suggest moderate growth, from 2.11 million tons in 2019 to approximately 2.43 million tons in 2024.

Bioplastics are already used in a variety of applications, including packaging materials, food containers, disposable cutlery, and even fabrics. In general, they offer several advantages over traditional plastics, including reduced greenhouse gas emissions during production and disposal, lower use of finite resources, and better biodegradability. In reality, each bioplastic is a material of its own, with its limitations and potential.

What are the most common bioplastics?

Thanks to regulatory evolution pushing toward sustainable solutions and increased awareness of the environmental damage caused by conventional plastic, bioplastics are becoming increasingly popular. This has led to intensified research and efforts to create a virtuous cycle around these products. To mention some examples of bioplastics and their most frequent uses:

- Polylactic acid (PLA): used in packaging materials, disposable tableware, and biodegradable bags. Discovered by the chemist Wallace Hume Carothers (also the inventor of nylon) in the ’30s but mass-produced many decades later.

- Starch-based bioplastics: used in food packaging and disposable tableware.

- Cellulose-based bioplastics: used in the production of clothing, food packaging, and consumer goods.

- Polyhydroxyalkanoates (PHA): used in medical devices, drug delivery systems, and biodegradable packaging. PHAs are polymers synthesized by various bacteria genera (Bacillus, Rhodococcus, Pseudomonas, etc.) through the fermentation of sugars or lipids.

- Biodegradable polyethylene (PE): used in compostable bags, packaging materials, and agricultural films.

Where to dispose of bioplastic waste?

As seen in this article, waste collection in Italy discriminates plastic waste based on the type of product rather than the material, at least during collection. In short, packaging and wrapping materials should be thrown into recyclables, but plastic objects should not. In a second phase, recyclable material will be separated from the portion of differentiated material.

The same applies to bioplastics, with an additional precaution: bioplastic packaging that is also biodegradable and compostable should be thrown in organic waste, not in plastic bins. However, it is necessary to verify with local regulations because this is not true throughout Italy.

What are the challenges of bioplastics?

Bioplastics are already a reality, but there are some challenges and barriers associated with their production and use. Some of these include:

- Cost: the production of bioplastics is still more expensive than traditional petroleum-based plastics. This is due to the high cost of raw materials and current limitations in production technology.

- Scalability: bioplastics production is currently limited, and scaling up to meet global market needs is a significant challenge.

- Performance: bioplastics still generally have lower performance than traditional plastics in terms of durability, robustness, and resistance to heat and chemicals. This makes them unsuitable for certain applications, such as in the automotive and electronics industries.

- Lack of infrastructure: there is currently a lack of infrastructure for the collection, processing, and disposal of bioplastics, making it difficult to integrate them effectively into existing waste management systems.

- Public perception: there is still a lack of awareness and understanding by the public about bioplastics, which can lead to confusion and misinformation about their advantages and limitations. Incorrect differentiation or the lack of appropriate places to dispose of such waste significantly reduces the value of the potential benefits of these materials.

- (Un)sustainable cultivation: the cultivation of biomass raw materials for bioplastic production can be harmful if not managed to maintain a proper balance with food crops and local biodiversity.

Despite all this, bioplastics are an important part of the effort to create a more sustainable future for our planet. By reducing the use of finite resources and improving the sustainability of plastic production and disposal, bioplastics can contribute to creating a greener and more sustainable future.

What to remember

The term bioplastic is used with different meanings, but in general, it is used to indicate a more sustainable alternative to conventional plastic. Currently, bioplastics make up only about 1% of the world’s annual plastic production. There are different types of bioplastics (such as polylactic acid or cellulose or starch-based bioplastics), each with its limitations and potential realized in its application in certain end-uses. Despite bioplastics appearing as a possible solution to the plastic pollution problem, there remain enormous challenges, such as costs, lack of infrastructure, scalability, public perception, and performance not always on par with conventional plastic.

Further information

Website of European Bioplastics (in English): here

Website of Assobioplastiche: here